1.Offer the most professional consultation and design.

2.Arrange production based on customers’ requirements in all aspects.In the process of production, real-time dynamic can be sent at any time, making it convenient for guests to understand the schedule.

3.Attach regard to the spirit of contract. Once a promise is made, it will be realized. Specific performance:strictly punctual shipment .

For each set of products we sell, each design has been carefully considered by the experts after analyzing the details of customer needs .

- Description

- Inquiry

Dust source: process of steel production: mining, dressing, smelting, refining etc.

Specific dust collector conditions:

(1)raw material field (2)sintering or coke oven (3)blast furnace (4)converter (5)continuous casting, rolling

Smoke composition: 40-60% iron oxide, graphite powder, oxide of calcium, silicon and magnesium.

Gas: Carbon monoxide,carbon dioxide, sulfur dioxide, hydrogen sulfide,nitric oxide and H2O.

Typical use environment:

Electric furnace dust removal solid: ZnO, Fe2O3, CaO, SiO2 etc.

Graininess: 0-2um 51%, 2-5Um 19%, 5-10um 13%, >10um 17%

Electric furnace dust removal gas: O2 0.75%, CO2 29.72%, CO 12.9%, N2 54.38%, H2O2 21.

We have a professional technology to deal with dust collectors of steelmaking. Please click on the link below to contact our experts directly.

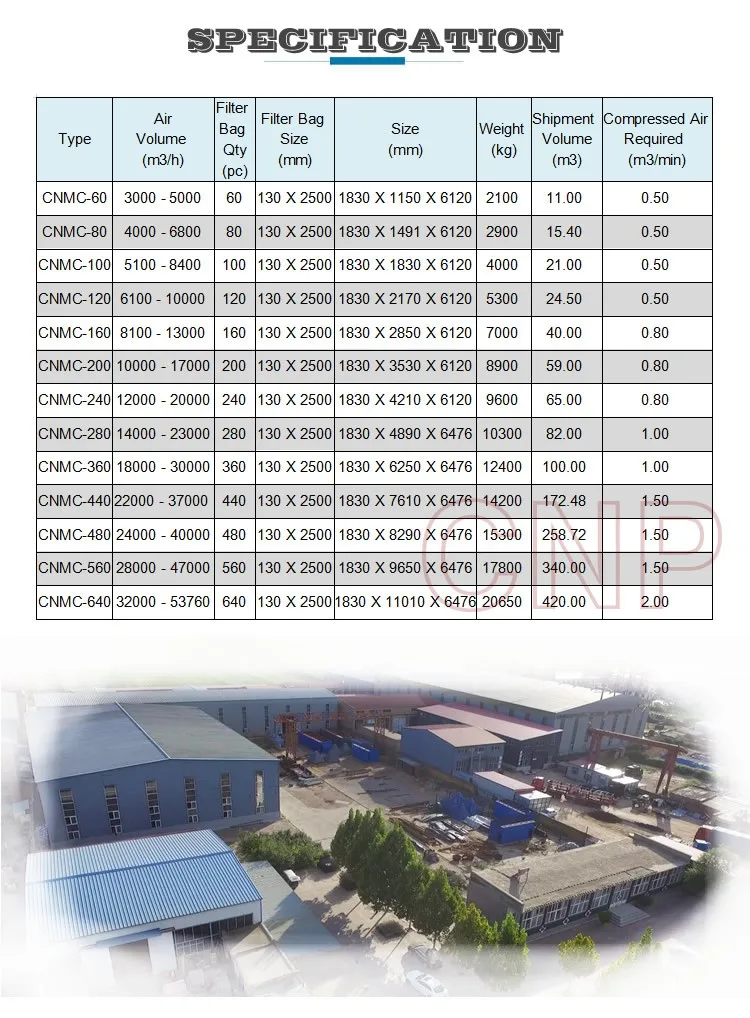

CNMC

CNMC type bag dust collector is a medium size offline gas tank pulse dust collector machine and mainly apply to the high dust concentration and large air volume application.And this type is used to clean dust from building materials production such as wooding, sanding, stone, cement, concrete, tile and glass.Adopt to the chambers cleaning .One of chambers is being cleaned while other chambers doing filtration working.

CNMC series pulse bag filter /stone dust collector machine are composed by the upper box, middle box, hopper box and ladder, platform, storage tanks, pulse valve, screw conveyor, discharge valve, electrical control cabinet, air compressor, filter bag, filter cages, etc. All parts are made according to the national standards and customer’s requirement.

Blowing system: the spray pipe, pulse valve, PLC controller, according to the nature of dust and working environment reasonably adjust the soot cleaning cycle and pulse injection time.

Ash hopper and ash discharge part,motor, reducer, screw conveyor, unloading, etc.

Our design standards of stone dust collector machine follows:

① Meet the shipping standard of export containers.

② Ensure maximum assembly product design.The purpose is: when the product arrive at the destination, the guests can be the most convenient for assembly.

③ Can make a complete set of equipment flange connection, convenient installation and disassembly.Reduce customer’s welding workload.

④ Promise that the designed product’s pressure resistance is greater than the maximum working pressure of the negative pressure fan in order to prevent product damage due to excessive fan pressure.

Package standardize of sawmill dust collection systems

1.Wrap moisture-proof film to prevent dampness abrasion during transportation.

2.Electronic components are packed in wooden cases or be fixed for shipment

3.When products are boxed in container, use foot bolts for fixing

4.Accessories products with carton or woven bag packaging

5.Carton packaging control products and mark shipping directions

6.Electrical products will be fixed or wrapped cotton packaging.

7.The integral device without splitting shall be fixed with wooden strips nailed at the corners of the box

We promise well-designed drawing and punctual shipping.

Our features of stone dust collector machine