- Opis

- Zapytanie

e Dust filter bag for Industry

INTRODUCTION

Filter cartridge is a kind of common dust catching device. The characteristic is: high capture rate, small resistance, easy to into the flue, itp. They are widely used for particulate matter, food and beverage industry lampblack, asphalt smoke pollutants such as sampling, chromium acid fog, acid mist.

According to the material, it can be divided into glass fibre filter cylinder and corundum filter cartridge, daily application is the most widely glass fibre filter cylinder. Glass fibre filter cylinder made of super fine glass fiber to 0.5 mu m above dust capture rate can reach more than 99.9%. But due to the production process, some cartridge quality problems, affects the efficiency of capture, in gas monitoring, the sampling error analysis on monitoring results is greater than the influence.

Struktura i zastosowanie

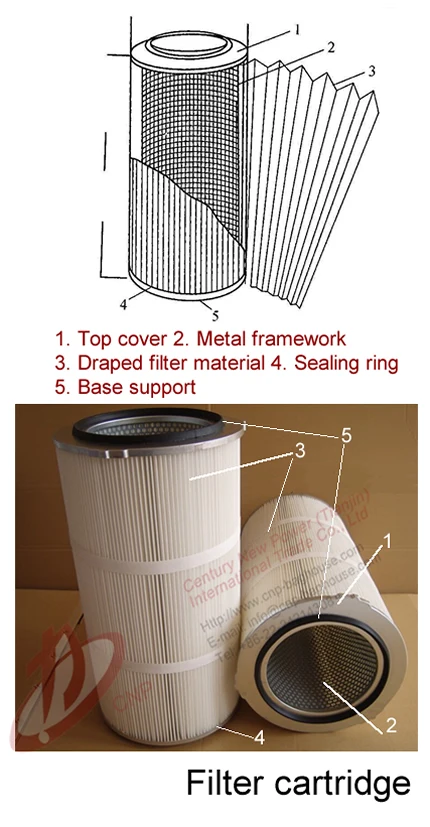

The structure of the filter cartridge, it often has the top cover, metal framework, folded filter material and base parts, itp. Filter cartridge is calculating the length of the filter material folded into fold, fore and aft adhesive to drum. The drum internal is supported by metal frame. The cartridge upper and lower fixed with cover and base. It has two types: one kind is inside and outside protected with galvanized steel plate; Another is the outer wall without galvanized steel plate protection, it is easy to dedusting.

Specyfikacje

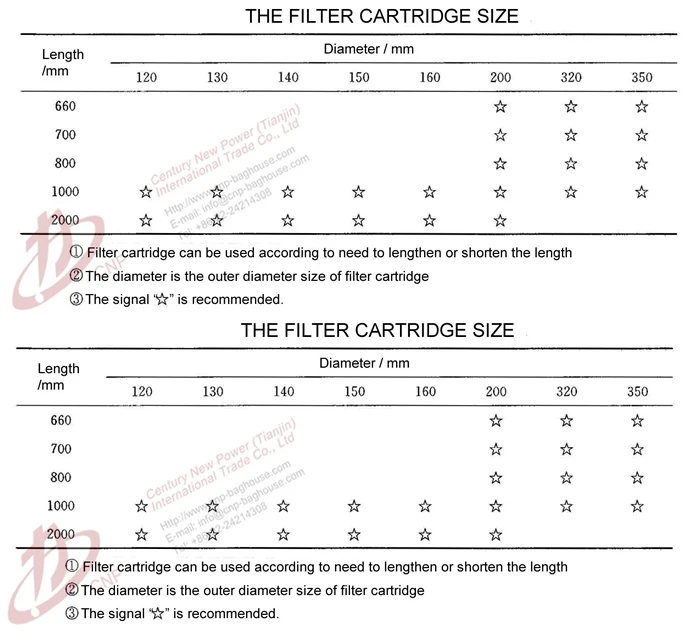

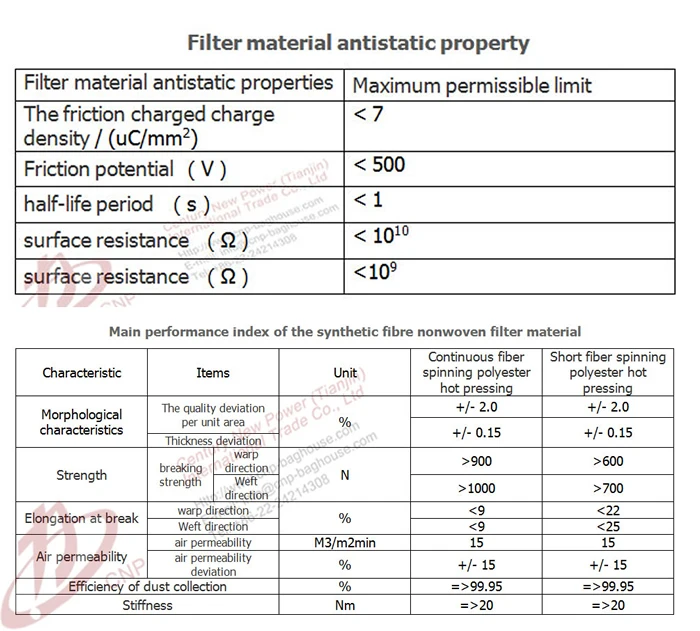

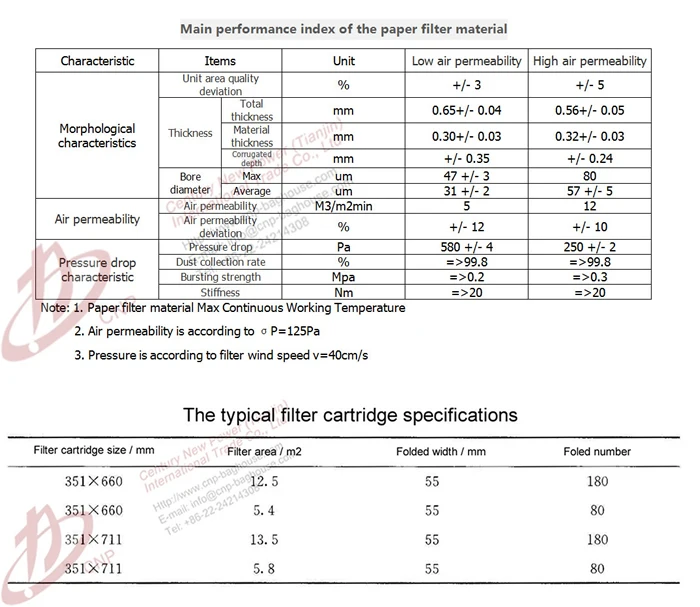

The specifications of the commonly used diameter of the filter cartridge is 120-350mm, długość to 660 – 2000mm. Please see the data as following:

Filter cartridge characteristic

The performance of the filter material include: physical and chemical properties, mechanical properties and filtration performance. For these performance, it takes physico-chemical properties of the fiber in filter, and the organizational structure of the filter material and manufacturing process, itp.

1. Physical and chemical property

Po wybraniu materiału worka filtrującego i określeniu specyfikacji worka filtrującego, będziemy przetwarzać worek filtrujący, ponieważ ma znaczenie następujące uwagi:

(1) Quality. Quality generally called heavy cloth, it refers to the quality of area of filter material (g/to2). Due to the material and the structure of the filter material is the most intuitive to reflect on the quality, so the quality key to filter material performance is the most basic and the most important indicator.

(2) Grubość. Thickness is one of the physical properties. It is more influence on the permeability of filter material, wear resistance, itp.

(3) Density and heat resistance of heat-resistant.

(4) Electrostatic resistance. Gas movement or sit grain collision will make some filter material charged. The influence of the process is two aspects. One side is opposite charges attract. the dust particles from the air to the electric fungus instead of filter material movement, too big wide filtration efficiency. Adverse – surface electrostatic and cutting force is not necessarily at the end of the filter section disappear, make clear ash is difficult. In addition, due to the charged dust accumulation, higher static voltage, with ginger produced an explosion caused by spark. Przestrzegamy surowych standardów jakości przetwarzania, zgodnie z rysunkami projektowymi i procesem operacyjnym. Nasz pracownik spełnia wymagania narzędziowe i odzieżowe, obuwie i czapki, zakaz palenia.

Working occasions

In industry dust collection

Power Stations

Filtered dust

Flue ash, discharging flue ash

Coal dust

Building and Construction

Cement, furnace dust, gypsum, limestone, finely ground quartz,

Calcium hydroxide, lead monoxide, quicklime, acid crystals,

Pure clay, phosphates, magnesite concentrate, finely ground

fluorid, production of aluminum

Chemical Industry

Thomas meal (Fertilizer)

Rubber compounds, sinter dust, catalysts

Sodium sulfate

Soap powder

In machinery top:

Silos / Tanks

Discharging systems

Warehouse units

Mixing equipment

Homogenizing systems

Chute Bottoms

Conveyor systems

Ventilator systems

Aeration systems

Powder Coating Machinery

Bottoms for sinter basin

st Filter bag for High temperature cement industry dust collection waterproof application

- 1. Zapytania szybko odpowiadają w ciągu 24 godziny.

- 2. Serwis pogwarancyjny, natychmiastowa odpowiedź, Podręcznik instalacji inżyniera. Odpowiedzi na problemy ze sprzężeniem zwrotnym zostaną udzielone w ciągu 24 godziny. Możemy zorganizować przybycie profesjonalnych inżynierów do lokalizacji sprzętu w ciągu 48 godziny pracy po rozwiązaniu problemu.

- 3. Konstrukcja odpylacza zgodna ze specyfiką technologii odpylania. Projekt sieci wiatrowej dla całego systemu. Być optymalnym projektem konstrukcji.

- 4. Najniższa cena sprzętu w całej sieci w alibaba Zapraszamy do stawki ceny. Jeśli nasza cena jest wyższa, zwrócimy Ci dwukrotność podanej przez nas różnicy w cenie. Prosimy o powiadomienie przed podpisaniem umowy z nami. Zgodnie z naszą zasadą dobrej wiary.

- 5. Sprzęt filtrujący worek skończył się 20 lat życia zawodowego.

- 6. Związane z częściami zamiennymi sprzętu, Upewnij się, że części zamienne znajdują się w środku 20 lat.

- 7. Jeśli akcesoria zatrzymają produkcję lub aktualizację, aby zapewnić normalne użytkowanie części zamiennych, i zwracaj uwagę na rok przed zatrzymaniem produkcji części zamiennych.

- 8. Zapewnij łatwą obsługę i absolutnie żadnych obaw o przyszłość