- Description

- Inquiry

INTRODUCTION

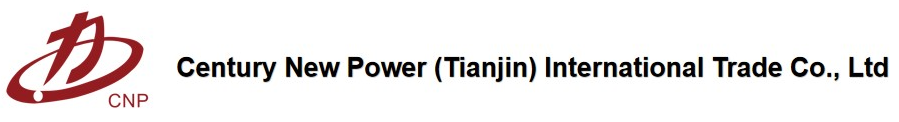

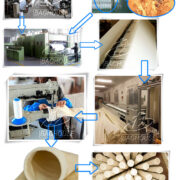

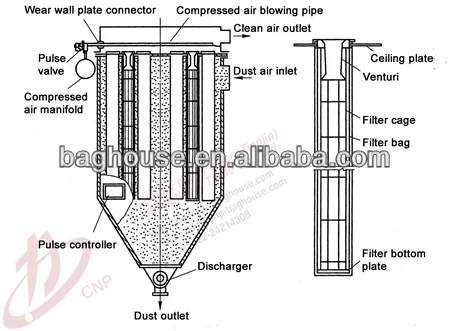

Filter bag is the core of the dust filter components. The filter bag has the strict requirements on design, filter material cutting, woven technology etc. These requirements are very important for the normal operation of the bag filter and convenient maintenance, and it is great significance to enlong the service life of the filter bag.

Structure and application

Filter bag are composed by woven filter material bag body and supported in role, snap ring, clamp, chain hoist, etc. The rest of the filter bag dust collector and its accessories are the venturi tube, frame, mouth of elastic ring, etc.

Specifications

The diameter of the filter bag is 115-200mm, length is 2000 – 9000mm, the specifications of the commonly used filter bag is 120 – 160 mm diameter, 2000 ~ 6000mm length.

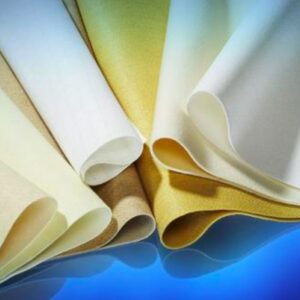

The Nomex material nature and the felt after treatment

Meta-AramidNeedle felt(NOMEX)

Construction =Needle Felt

Fiber Composition = Polyisophthaloyl metaphenylene diamide fiber (Nomex) 100%,

Scrim Composition= Nomex yarn,

Felt Area Weight = 500 g/m2

Thickness = 2-2.5mm

Density = 1.37-1.38g/cm3

Mean Air Permeability = 25m3/m2min @12.7H2O (+/- 5%)

Breaking Strength- Warp=>1000 N/5cm X 20cm

Breaking Strength- Weft= >1200 N/ 5cm X 20cm

Breaking Elongation – warp=<40%

Breaking Elongation -weft=<40%

Operating Temperature = 200deg.C

Recommended Maximum Continues =220 deg.C

Recommended Maximum Surge = 220 deg.C

Chemistryacid resistance : good

Chemistry alkaliresistance : good

Very good resistance for abrasion

Hydrolyze stability: bad

Bad for strong alkali

Limited oxygen index (LOI) 28

Finnish : burn or PTFE membrane coating

Filter bag processing need attention

Filter bag processing matters that should be paid attention:

After the selection of filter bag material and determine the specifications of the filter bag, we will process the filter bag as following attention matters:

(1) Precise design required size of the filter cloth for filter bag parts, the filter cloth will larger than the actual amount design size, to leave a spare for weaving.

(2) To choose the right filter bag accessories, specifications and check its quality. The filter bag accessories should match the filter bag quality requirements.

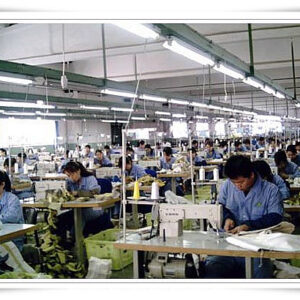

(3) We make the filter bag line drawing, cutting, sewing on automatic production line. When the filter bag need manual processing, we will open it on the operation platform, and with certain pulling force to keep it is flat.

(4) We keep the strict processing quality standards, according to design drawings and operation process. Our worker meet the requirements of tooling and clothing shoes and hats, no smoking.